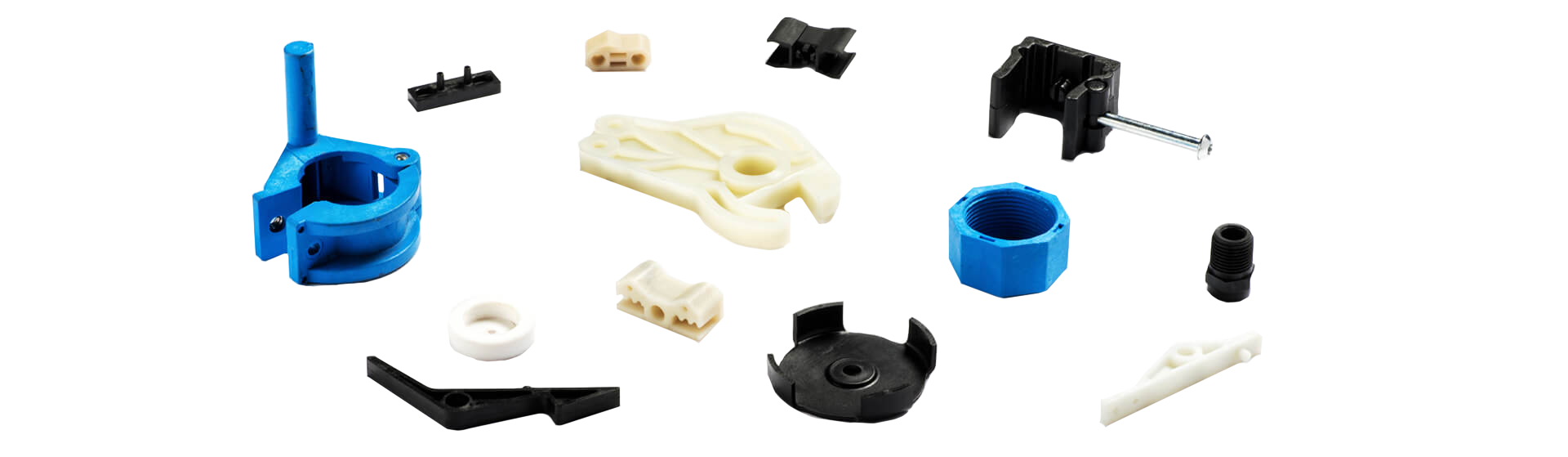

PLASTIC INJECTED PARTS

PLASTIC INJECTED PARTS

Injected plastics manufacturers

IMA offers a complete project development service for any client who needs to find a solution through injected plastics.

A complete service that is carried out through a process engineering that includes the design phase of the prototype, the manufacture of the mold, the exhaustive control of the quality of the pieces, production in series and ends with the delivery of the finished product to the customer.

Experience and advice to design parts

We offer our experience in each of the projects, advising on the entire manufacturing process, whether from the design of parts, to the manufacture of molds or parts, and in the production of these.

We provide technical advice on each of the projects for each part, choosing the most appropriate raw materials, the design process and the manufacture or adaptation of the molds. All achieved according to the technical specifications offered by the client.

IMA provides Plastic Injection

Plastic injection has an added value over other materials and techniques, since it is a process that is characterized by rapid manufacturing, obtaining large quantities of the desired part in a very short period.

IMA manufactures all types of parts through the plastic injection procedure. Working with different materials such as thermoplastics, polymers and polyamides, we can successfully face any challenge that customers may pose.

We can develop any type of part or product using injected plastic, with varying shapes and sizes, and offering the plastic injection service for any job.

The development of parts can be done using the molds provided by the customer, or by making the injection molds in-house at IMA, whatever is the best option. There is also the possibility of finishing the entire manufacturing process of the injected parts, through complementary services such as assembly of parts or final finishes.

Thanks to the wide experience that IMA has acquired during our more than 30 years in the sector of magnetism, we offer the opportunity to carry out work on both magnet over-injection and elaboration of custom-injected magnets for any industrial sector.

IMA offers its clients the possibility of managing the entire process of creation and elaboration of parts injected in plastic. It includes the phases of:

Customer Proposal

Analysis

3D part design

Mold Design and Manufacturing

Serial manufacturing of parts

Customer Delivery

FABRICATION PROCESS

FABRICATION PROCESS

Design and simulation of the pieces:

The most advanced software tools in the sector are used to design the injected plastic parts to obtain greater precision and thus avoid unnecessary costs. In the design process, computer simulations that analyze the work limits of the piece are included.

Development of plastic injected parts:

After the design of the product to be injected, IMA offers the product development service. The development starts from the design that the client provides, or is provided by the company, to develop new and more efficient products. In short, IMA works together with customers to improve the performance of plastic injection projects and increase opportunities for your business.

In this phase a conceptualization is carried out, a design of the first prototypes, the choice of materials and different tests are also carried out with the mold until the final part is manufactured.

Advantages of plastic injection

The injection of plastics produces manufactured parts with different properties to meet the product specifications. This allows us:

• To ensure the most suitable plastic material for the part is used for each application.

• To achieve the most economical solutions, where parts have complicated designs or whose manufacture is very expensive by other processes.

• To make the part in a single manufacturing step.

• To make the entire process automatic, reducing costs and manufacturing time.

• To make it possible to manufacture an unlimited number of parts quickly.

• To offer superior product quality compared to other manufacturing processes.