PLASTIC INJECTION MOLDS

PLASTIC INJECTION MOLDS

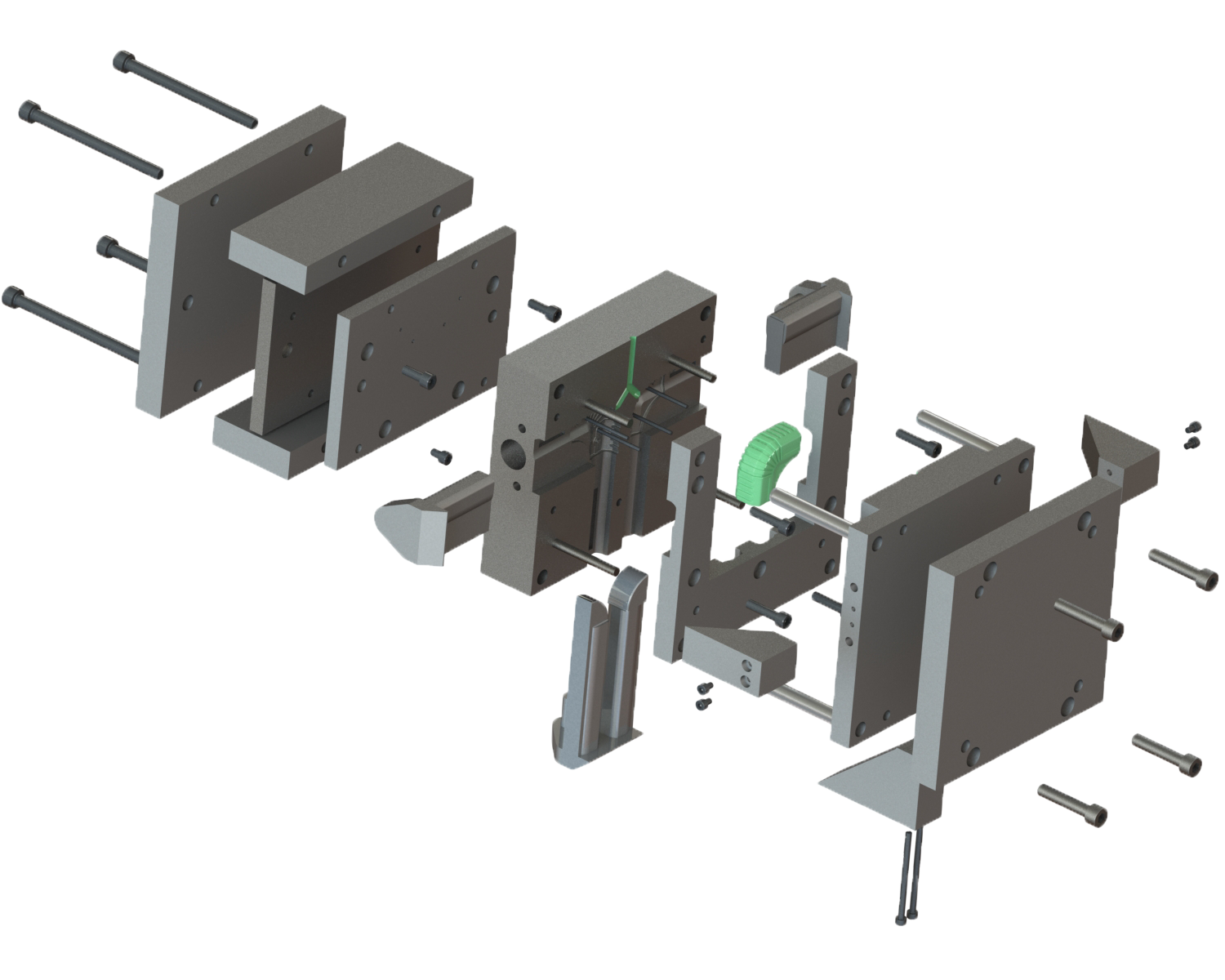

Injection Mold Manufacturing

Injection molds must be of high quality and be manufactured with the highest precision, as they will be used for the mass production of many parts.

IMA takes great care of the design and follow-up during the manufacturing process of all our molds, reducing costs and providing more cost-effective solutions that require less maintenance.

For this manufacturing process, a professional team using the latest and most efficient machinery and experience is necessary.

Injection molding process

Plastics injection molding is a manufacturing process where plastic granules are first introduced and then melted, compressed and injected with the plastic material (polyamides, polymers and thermoplastics).

Once the plastic material is melted and a hot resin is obtained, it is injected under pressure into the mold cavity, until the entire mold is filled. Once it solidifies, part of the mold is extracted by means of ejector pivots, and the part placed into a container.

During the manufacturing process the equipment is programmed to control the filling pressure, anticipating possible aesthetic problems and verifying the quality of the parts in real time.

IMA manages and provides all manufacturing processes involved in making a mold, providing better quality, effectiveness, lower cost and shorter manufacturing times.

Project Reception

3D design creation

Prototype Engineering

Injection Mold Manufacturing

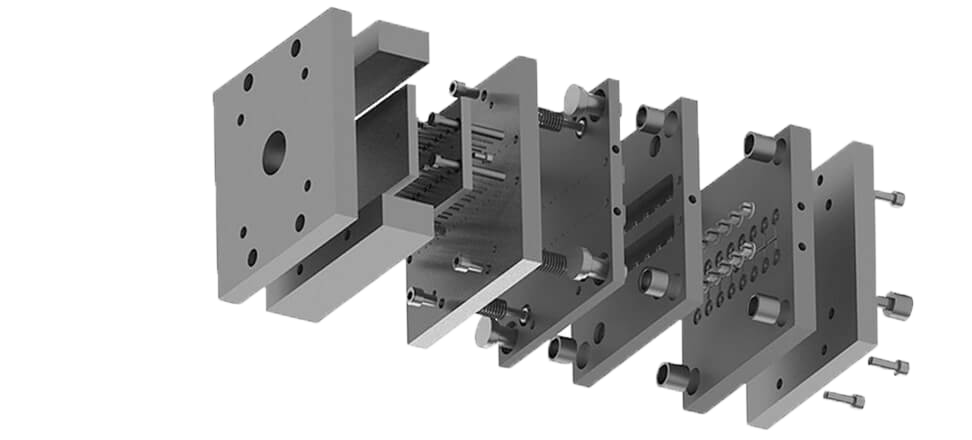

WE DESIGN YOUR CUSTOM MOLD

WE DESIGN YOUR CUSTOM MOLD

At IMA we design and manufacture all types of plastic injection molds for any sector of industry.

Thanks to the high-quality materials used when we make injection molds, we can optimize and control the entire manufacturing process.

To obtain the best results, we offer our clients the full range of manufacturing processes for injection molds and injected parts. We design and develop all types of molds and products to be injected.

We advise throughout the injection process, providing added value for our clients. The customer is accompanied throughout the manufacturing process with the best technical service.