PRODUCTS

PRODUCTS

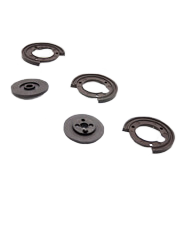

Injected magnets are magnetic products manufactured with high precision and tailored for each application.

CHARACTERISTICS

CHARACTERISTICS

Consult the properties (remanence, force, coercivity, temperatures ...) of the injected magnets collected in the following table of qualities.

CONSULT QUALITY TABLE

|

Energy product | Remanence | Rev. temp.-coeff. | Coercivity | Magnetising | Max. | Density | |||||||||

| (B*H)max. | Br | of Br | field | operating | ||||||||||||

| strength | temperature | |||||||||||||||

| Plastic-bonded, injection-moulded hard ferrite magnets | kJ/m3 | kJ/m3 | mT | mT | approx. | HcB | HcJ | min. | approx. °C PA 6 4) | approx. °C PA 12 | approx. °C PPS 5) 6) | approx. | ||||

| (typ.) | (min.) | (typ.) | (min.) | %/K | kA/m | kA/m | kA/m | g/cm3 | ||||||||

| (min.) | (min.) | |||||||||||||||

| HF | 14/22 | p | anisotropic | 14,5 | 14 | 275 | 265 | -0,19 | 180 | 220 | 800 | 120-160 3) | 120-14 03) | 220 3) | 3,6 | |

| HF | 16/19 | p | anisotropic | 16,5 | 16 | 290 | 280 | -0,19 | 160 | 190 | 800 | 13 | 120-140 03) | 3,7 | ||

|

Energy product | Remanence | Rev. temp.-coeff. | Coercivity | Magnetising | Max. | Density | ||||||||||

| (B*H)max. | Br | of Br | field | operating | |||||||||||||

| strength | temperature | ||||||||||||||||

| Plastic-bonded, injection-moulded rare earth magnets | kJ/m3 | kJ/m3 | mT | mT | approx. | HcB | HcJ | min. | approx. ºC | approx. °C | approx. | ||||||

| (typ.) | (min.) | (typ.) | (min.) | %/K | kA/m | kA/m | kA/m | PA 12 | PPS 5) 6) | g/cm3 | |||||||

| (min.) | (min.) | ||||||||||||||||

| NdFeB | 30/60 | p | isotropic | 33 | 30 | 435 | 420 | -0,11 | 2) | 290 | 600 | 2800 | 120-140 | 3) | 120-160 | 3) | 4,1 |

| NdFeB | 37/60 | p | isotropic | 39 | 37 | 475 | 465 | -0,11 | 2) | 320 | 600 | 2800 | 120-140 | 3) | 120-160 | 3) | 4,5 |

| NdFeB | 42/60 | p | isotropic | 44 | 42 | 510 | 490 | -0,11 | 2) | 335 | 600 | 2800 | 120-140 | 3) | 120-160 | 3) | 4,7 |

| NdFeB | 48/60 | p | isotropic | 50 | 48 | 540 | 530 | -0,11 | 2) | 360 | 600 | 2800 | 120-140 | 3) | 120-160 | 3) | 4,8 |

| NdFeB | 55/60 | p | isotropic | 57 | 55 | 570 | 560 | -0,11 | 2) | 375 | 600 | 2800 | 120-140 | 3) | 120-160 | 3) | 5,2 |

| NdFeB | 27/80 | p | isotropic | 29 | 27 | 410 | 400 | -0,13 | 2) | 270 | 800 | 2800 | 120-140 | 3) | 140-180 | 3) | 4,1 |

| NdFeB | 32/80 | p | isotropic | 34 | 32 | 445 | 435 | -0,13 | 2) | 295 | 800 | 2800 | 120-140 | 3) | 140-180 | 3) | 4,4 |

| NdFeB | 38/80 | p | isotropic | 41,5 | 38 | 485 | 470 | -0,13 | 2) | 320 | 800 | 2800 | 120-140 | 3) | 140-180 | 3) | 4,7 |

| NdFeB | 43/80 | p | isotropic | 46 | 43 | 515 | 505 | -0,13 | 2) | 340 | 800 | 2800 | 120-140 | 3) | 140-180 | 3) | 5 |

| NdFeB | 46/80 | p | isotropic | 48 | 46 | 530 | 515 | -0,13 | 2) | 350 | 800 | 2800 | 120-140 | 3) | 140-180 | 3) | 5,2 |

| NdFeB | 49/80 | p | isotropic | 52 | 49 | 555 | 545 | -0,13 | 2) | 365 | 800 | 2800 | 120-140 | 3) | 140-180 | 3) | 5,3 |

| NdFeB | 76/110 | p | isotropic | 88 | 76 | 700 | 660 | -0,13 | 2) | 460 | 1100 | 2400 | 100-120 | 3) | 100-120 | 3) | 4,8 |

Type of material

Magnetic powders: ferrite or rare earth Thermoplastics

Composition

NdFeB / SmCoFerritaPA6 / PA11 / PA12

Work temperature

From 100ºC to 200ºC

Advantages

Resistance to corrosion Molding diversity

ADVANTAGE

The mechanical and magnetic values will vary depending on the materials. These materials used in the injected magnets are mainly polyamides PA6 - PA12 - PPS Phenylene Polysulfide.

This type of injected magnets are more resistant to corrosion than sintered materials, for this reason they can be used in most applications without special coatings.

Injected magnets also have geometric advantages, just like in the plastic molding process, we can achieve complex geometries and with much tighter tolerances than in traditional sintered magnets.

WORK TEMPERATURE

With this type of injection materials maximum temperatures of 100ºC of work are obtained for PA12 and approximately 120ºC for PA6. For working temperatures of 200 ° C, PPS (Phenylene polysulfide) is used, which allows good behavior at high temperatures. Epoxy resins that can be used up to temperatures of 120ºC.

APPLICATIONS

APPLICATIONS

The scope of application of the injected magnets is very wide. We manufacture products for different industrial sectors, such as automotive, electronics, robotics ...